Understanding the Anatomy of Concrete Pump Spare Parts:

In the dynamic world of construction, where precision and efficiency are paramount, the reliability of concrete pump spare parts is indispensable. However, even the most robust systems encounter issues from time to time. In this comprehensive guide, we delve into the art of troubleshooting common problems with concrete pump spare parts, offering practical solutions and preventive measures for construction professionals.

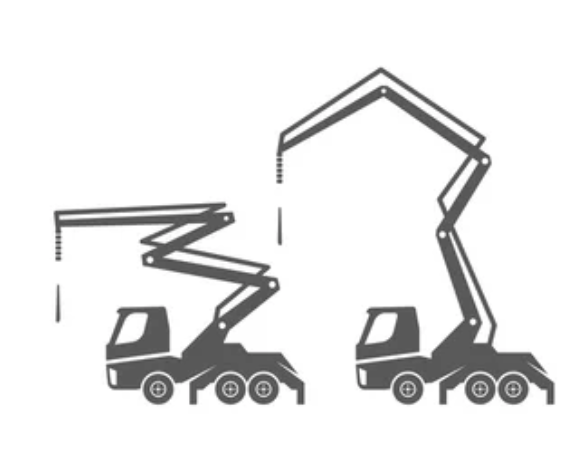

Before we embark on the journey of troubleshooting, let’s acquaint ourselves with the crucial components that make up a concrete pump system. From wear plates and seals to pipes and hoses, each part plays a pivotal role in the seamless flow of concrete. Understanding this anatomy is the first step in effective troubleshooting.

Common Issues:

Leakage is a common concern in concrete pump systems and can be attributed to various factors. Whether it’s a worn-out seal, a damaged hose, or a loose connection, identifying the source of leaks is crucial. Our guide will provide a detailed examination of potential leakage points, accompanied by practical steps for locating and addressing these issues swiftly.

Reduced Pumping Efficiency:

When pumping efficiency dwindles, it can significantly impact project timelines and costs. This section will explore the factors contributing to reduced pumping efficiency, ranging from worn-out wear parts to pump malfunctions. With troubleshooting steps outlined, operators can restore optimal pumping performance and minimize downtime.

Unusual Noises:

Unusual noises in a concrete pump system can be disconcerting and indicative of underlying issues. This section will act as a diagnostic manual, helping operators interpret different sounds, from grinding and squealing to banging. With a thorough understanding, troubleshooting methods will be presented to eliminate these unusual noises and ensure smooth operation.

Preventive Measures: Regular Inspections:

An ounce of prevention is worth a pound of cure. Regular inspections serve as the backbone of preventive maintenance. This part of the guide will emphasize the importance of routine visual assessments, offering guidelines for establishing inspection schedules. By catching potential issues early, operators can prevent major disruptions to their projects.

Preventive Measures: Proper Lubrication and Maintenance:

Proper lubrication is the lifeblood of moving parts in a concrete pump system. This section will delve into the role of lubrication in preventing wear and tear. From selecting the right lubricants to step-by-step instructions for maintenance practices, the guide aims to equip operators with the knowledge to extend the lifespan of critical spare parts.

Case Studies: Real-Life Troubleshooting Success Stories:

Learning from real-world experiences can be invaluable. This part of the guide will present case studies where effective troubleshooting led to successful problem resolution. Through these stories, construction professionals can gain insights into the practical application of troubleshooting techniques in various scenarios.

Collaboration with Experts: Seeking Professional Guidance:

Acknowledging the complexity of some troubleshooting scenarios, this section advocates for collaboration with experts and manufacturers. Sometimes, seeking professional assistance is the most prudent approach. The guide will provide guidance on when to reach out for expert advice and how to foster fruitful collaborations.

Troubleshooting Toolkit: Essential Tools for Every Operator:

Every troubleshooter needs the right tools for the job. This section will compile a list of essential tools for troubleshooting concrete pump spare parts. From diagnostic tools to measuring instruments, operators will be equipped with a troubleshooting toolkit tailored for on-site use.

In the ever-evolving landscape of construction, mastering the art of troubleshooting common issues with concrete pump spare parts is a skill that sets professionals apart. This comprehensive guide serves as a roadmap for operators, offering insights into the intricacies of troubleshooting and preventive measures. By adopting these practices, construction professionals can ensure the seamless operation of their concrete pump systems, contributing to the success of their projects and the overall efficiency of the industry.

This post has been sponsored by our amazing partner at Concrete Abilene TX. We would not be able to do what we do without them!